People have been using natural stone as a building material since the dawn of human history. Once used to erect massive temples, tombs, and monuments, it has become the material of choice for homeowners who want a unique touch of natural beauty in their home.

How is Granite Formed?

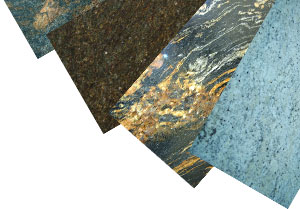

Natural granite comes in a stunning array of different colors and patterns, making it adaptable to any sort of style or design aesthetic. Granite is an igneous rock, which means it is formed when molten rock cools and solidifies. The colors we see in various granite slabs are a result of different minerals mixing in with the granite when it is still in its molten state. As this mixture of minerals solidifies, different mineral densities and veins form the beautiful striations and patterns that are so highly sought after in today’s granite market.

Natural granite comes in a stunning array of different colors and patterns, making it adaptable to any sort of style or design aesthetic. Granite is an igneous rock, which means it is formed when molten rock cools and solidifies. The colors we see in various granite slabs are a result of different minerals mixing in with the granite when it is still in its molten state. As this mixture of minerals solidifies, different mineral densities and veins form the beautiful striations and patterns that are so highly sought after in today’s granite market.

Where Does Granite Come From?

The granite slabs at NEKA Granite Marble Quartz have quite the journey before they reach our showroom. Granite, Marble, and other types of natural stone, are mined in huge quarries all over the world. The majority of natural stone is imported from Brazil, Italy, Spain, and China. Brazil is known for its granite quarries, while Italy produces a majority of marble and onyx.

The process of mining natural stone starts by cutting a large block of the desired material out of the quarry, making sure that it is solid throughout, without any cracks, fissures, or other imperfections. Even the slightest imperfections can cause problems down the road when the stone is cut into slabs and used for construction.

Detail of huge Thassos white marble quarry (mine) with grabber

Once the block has been removed, it is cut into slabs with gang saws. This cutting process can take up to 48 hours to complete. Once the slabs have been cut, they need to be covered with resin and cured in an oven. This resin coating fills any minor fissures or imperfections and seals the stone to make it ready for polishing or one of our other finish options.

After the slabs have been sealed and cured, they are shipped out to distributors like NEKA. When the slabs reach our warehouse, we inspect each one to make sure it is free of imperfections, we may do a quick polish and buff to make them really shine, and finally we photograph each slab to make it easy to show you all of the options when you come in to purchase a new countertop.

How Do We Turn Slabs into Finished Products?

Granite’s journey from quarry to countertop still has a few more steps after it reaches our warehouse as a slab. Obviously, each slab must be cut down to size for the project it is being used for, and in most cases refinished before sending it out for installation.

Granite’s journey from quarry to countertop still has a few more steps after it reaches our warehouse as a slab. Obviously, each slab must be cut down to size for the project it is being used for, and in most cases refinished before sending it out for installation.

To cut our slabs down to size we use our specialized CNC (or Computer Numerical Control) routers and saws to make sure the slab is cut down to exact specifications. We utilize our CNC routers to add any special details to your countertop like a hole for a sink or other fixtures.

Once the slab is cut down to size, we use our automated multi-head edge processors to put your chosen edge on your new countertop with mechanical precision.

Finally, we apply your chosen finish to the stone to achieve the exact style you’re looking for. We have a wide variety of exclusive finishes that can help you personalize the look of your new countertop and fit it into your overall design scheme for your home.

After all that processing, your new granite countertop is ready for installation. Our highly trained crew of installation professionals make quick work of removing your old countertop and replacing it with your brand new granite countertop from NEKA Granite Marble Quartz.

Granite countertops are a remarkable feat of human ingenuity when you take the time to look at the whole process involved in their creation. It’s pretty incredible to think that your new countertop was once underground halfway around the world, and here at NEKA we are proud to bring you these high quality building materials from across the globe.

Click here to see more about our fabrication techniques and be sure to check out our gallery of fabrication photos to see the various types of equipment that go into manufacturing our quality stone products.